If you’re in the marine industry, it’s most likely you are generally dealing with a waterborne transport of different types. And depending on your role, you might be the one who’s in charge of ensuring things are running correctly. If you don’t know much about slip rings – you might not be able to do your job as efficiently.

Slip rings are one of the crucial components that keep the marine industry running – and even though they’re so small to the point where they look irrelevant.

In this post, you’ll find the primary function of slip rings, how they work and benefit the marine industry, and where else they make a great fit.

Here’s what you can expect to find in this article:

- The function of a Slip Ring

- How are Slip Rings Used in Marine Industry

- Where Else Can You Find Slip Rings

- Benefits & Advantages of Slip Rings

- Conclusion

The Function of a Slip Ring

If you don’t know much about slip rings, you might be surprised to find out the number of industries that utilize slip rings within some of their most common devices.

But why are slip rings so popular, and what is it they even do? If you’re already thinking whether there’s a way to replace slip rings – we’re afraid that we’re not quite there. And in fact, there’s no need to replace something that’s working so efficiently.

Upgrade? Maybe, but definitely not replacing.

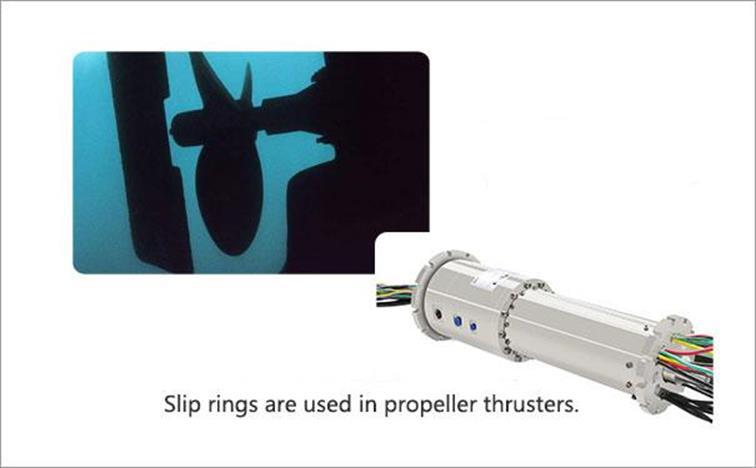

The slip ring has one main function, which is to make a connection between a rotary and stationary part of the device. Sounds simple?

It transmissions the power and electrical signal. While it might not mean a lot at first – image having a device that is rotating and yet isn’t able to keep up with the power or signal on the rotating part of the device.

Not only slip rings connect these two parts of a single device, but they also provide a lot more – which is a useful connection.

How are Slip Rings Used in Marine Industry?

Since the marine industry is quite a massive industry that mostly deals with waterboard transportation – you can already expect the need for slip rings.

There are way too many moving parts (let’s say, inside an industrial boat) that can’t afford inconsistency in power or electrical signal.

Slip rings in so many more ways. They even help in:

- offshore petroleum industry

- oceanographic industry

- seismic and maritime industries

Remember when we’ve mentioned how slip rings get upgraded from time to time? Something you should be aware of is that the marine industry relies on slip rings quite often.

Therefore, there are special slip rings made just for use in the marine industry. These slip rings are called Focal slip rings, and they’re designed and customized to function in extreme marine environments.

In some situations, regular slip rings just might not cut it – but that’s where slip rings from brands such as Moog or Moflon help out.

But how do slip rings actually help the marine industry?

One of the most significant examples is the winching, which is an essential part of the marine industry. There are specialized winching slip rings that can operate at higher voltage, come in bigger sizes, and have a bit faster rotation speed.

Where Else Can You Find Slip Rings?

Slip rings are very easy to find. Why? Because they’ve been used in almost any industry you can think of. Can’t you believe it?

Just think about one industry and check out if it’s listed down below.

Here are some of the industries where slip rings help on a regular basis:

- Automotive

- Oil and gas

- Mining

- Paper

- Plastic

- Rubber

- Printing

- Car washes

- Machinery

- Steel

- Tires

- Textile

If the industry you’ve thought of is on the list – there is the proof. If it’s not – no worries, since it’s most likely slip ring is utilized in less known industries around the world as well.

Of course, you will never find the same type of a slip ring in every one of these industries. Slip rings come in different shapes, sizes, and types.

You can think of a slip ring as an electromechanical device, which is very often customized to fit into any industry out there.

However, one thing always remains the same. Can you guess it?

It’s the working principle of a slip ring. The slip ring is always working in one way or another to connect the stationary and rotary parts of a device while transmitting power or signal.

But just as always, there’s an exception of slip rings use in DC motors.

Benefits & Advantages of Slip Rings

Believe it or not, slip rings are even used in AC and DC motors. And as you can guess, slip rings offer plenty of benefits and advantages since they’re used in almost any industry there is.

Here are some of the most known & common benefits of slip rings:

- Transmits power or signals in a rotary part of the device

- Can be used in any electromechanical system

- Improves mechanical performance

- Simplifies electrical systems

- Eliminates damage-prone wires away from the movable joints

- Have a high starting torque when used in an electrical motor

These are some of the most common benefits. Since slip rings are used in almost any industry out there, it’s hard to keep track of every single type and use of a slip ring.

However, this means that slip rings offer far more benefits, whether they’re as significant as these ones or not.

Conclusion

![]()

Slip rings are anywhere around you, and while this might sound crazy – it’s the reality we are living in. Many less significant parts of electromechanical devices have been upgraded or replaced – however, slip rings aren’t going anywhere.

You’ll be seeing slip rings in at least the next couple of decades before there are any major changes. If you’re in the marine industry, it’s most likely you’ve already come across a device such as a slip ring.

In case you didn’t know what it was – this article has everything you need to know about slip rings. Studying them can help you improve your skills, be aware of the connecting possibilities, and more.

How and where did you meet slip rings, your first time? Feel free to leave a comment below! Don’t be afraid to start a discussion!